November 17, 2012

Day 210

I wanted to share our experience with a topic that I hope you find very relevant - that of picking your architect and contractor. You may wonder, why talk about that now.. Well, I couldn't have written about this earlier even when I wanted to. There are things that we have learnt in hindsight for which we had no insight early on. It is only after being in the process for 6-9 months that I appreciate all the parameters one should consider while picking an architect and a contractor.

So, let's go back about 24 months back in time, i.e. November 2010 when we started this process of envisioning and designing the house.

For starters, there are a number of steps before you start to construct your house. It may not be obvious how these steps are sequenced and time each would take. And therefore, we all end-up under-estimating time and effort required to even start the process. Below is the typical chronological sequence leading up to house construction.

Build your own vision of house - House building is a very creative activity and like any new thing, you want to indulge yourself fully to enjoy it. House building is as much about knowing yourself as about building a physical structure. That's where it becomes either fun for some folks or frustrating chore for others. I have number of friends who would rather buy a pre-built house and are perfectly happy with that. There is absolutely nothing wrong in that! My first advice therefore is - You intrinsically want to build your own house to have fun doing it. Don't do it to compare or compete with anyone.

Think about parameters that would influence your house. These could be external elevation of the house, spaces within the house, budget, layout of the physical structure, levels within your house, reselling or renting house partially or fully, daily habits or routines of folks who would live in the house, and so on. While you do these, pay special attention to how you and folks who would live conduct their daily lives - what are their habits, what are their likes, dislikes or constraints, and how these might change over time. All of the influencing factors above help build a vision for your house. You may either document your vision through a document, or create a Google sketchup or anything in-between. Point is to have somewhat specific idea that describes personality of your house.

There is tons of material available on web and I'd suggest to make yourself familiar. You may also refer to various house design magazines, or read newspaper columns, or blogs such as this to arm yourself with experiences of others. The book that I found particularly helpful in our process is Designing Your Perfect House as it clearly and comprehensively articulates the whole process.

It is hard to put a time-limit on this step and my advice would be to set-aside time each week to build your vision. It is easiest to lose pace on this activity, or postpone it to later stage and doing so has the risk of either compromise, or having to start all over again after you have realized your own vision.

During the process, you may either feel you have a perfect idea of the house, or you may feel confused about what your house should look like. If you feel you have perfect idea, I would say stop now and proceed to the next step. However, don't be rigid about your idea - it will change. Allow for changes as long as they fit within your vision for the house. If you feel confused, keep looking and as you do research, jot-down items that you either really like, or really dislike. Over time you will see a pattern in what you really like or dislike and that will help you create a picture of how your house should look like.

Meet various architects - It is important to meet different architects as they have different styles and preferences. Some of the variations we have seen amongst architects were

That's all for now.. It has been a long post, but hopefully worth it. Feel free to point out any details you would have liked to see and I will see if I can incorporate it.There is tons of material available on web and I'd suggest to make yourself familiar. You may also refer to various house design magazines, or read newspaper columns, or blogs such as this to arm yourself with experiences of others. The book that I found particularly helpful in our process is Designing Your Perfect House as it clearly and comprehensively articulates the whole process.

It is hard to put a time-limit on this step and my advice would be to set-aside time each week to build your vision. It is easiest to lose pace on this activity, or postpone it to later stage and doing so has the risk of either compromise, or having to start all over again after you have realized your own vision.

During the process, you may either feel you have a perfect idea of the house, or you may feel confused about what your house should look like. If you feel you have perfect idea, I would say stop now and proceed to the next step. However, don't be rigid about your idea - it will change. Allow for changes as long as they fit within your vision for the house. If you feel confused, keep looking and as you do research, jot-down items that you either really like, or really dislike. Over time you will see a pattern in what you really like or dislike and that will help you create a picture of how your house should look like.

Meet various architects - It is important to meet different architects as they have different styles and preferences. Some of the variations we have seen amongst architects were

- Some architects build houses of contemporary style while others favor traditional style

- Some architects have a good eye towards attractive elevation while others are better at detailed planning of individual spaces.

- Some architects are fixated towards a feature of the house such as stairs or floor levels while others may be fixated towards earthy materials or concepts.

- Architects that are well reputed may relegate most of house design work to their sub-ordinates while relatively young architects themselves design the house. On the flip side, well-reputed architects have tons of design ideas and experience which very young architect may not.

- Some architects tend to design tens (if not hundreds) of houses in a year while others may only do 5-10 in a year.

- Some architects charge flat fee versus others that charge % of total house cost.

- Some architects have designated contractor that they work with while others work with any contractor of your choice.

I am sure there are other parameters as well but this hopefully provides rationale why it is important to get to know the spectrum to make an informed decision. Ultimately, there is no right or wrong decision, it is what you feel most comfortable with.

Next obvious question is how to get to know what type of architect you are dealing with - Well, you will never have 100% idea, but a few things that can help are

- Look at houses they have built. Don't rush to conclusion based solely on pictures, pictures can be very deceiving. It is important to visit the houses to get first-hand view of houses. While picking the house, pick a combination of relatively new (< 1 year old) house as well as somewhat older (2-5 years old) houses. Once you have seen 3-4 houses you might start to notice a pattern.

- Provide your requirements and ask if architect would make a mock design. This will give a sense of architects' vision in reference to your own.

- Do reference check with house owners. Often, pointed questions elicit better insight than a generic question.

Finalize an architect - No matter how many architects and how much analysis you do, there will never be surety while finalizing an architect. The point really is you want to have reasonably good idea of architect's style and should feel excited at the prospect of him building your house. For us, it was this intuitive sense when we finalized the architect who designed our house.

As you may have already guessed, above process does take few weeks to few months depending on your situation and there is always cost of over-analyzing. It is not unreasonable to expect 4-6 months to finalize an architect. Not that I recommend this approach, but we also know of friends who picked an architect and had to change their mind mid-way through their house design. While you'd lose retraining amount, it is better to cut your losses than to compromise on your dream house.

Some of the things that we learnt about our architect and why we feel very excited about him even today -

Iterate over design - You would typically meet architect to provide your requirements. Depending on architect, this meeting is either free-form or more structured. There are quite a few questionnaires available on web for design of spaces. Here is an example of questionnaire for House overall or for specific room such as Kitchen. Find one that you are most comfortable with and fill that out. This will help clarify your thoughts even if you didn't share with your architect. We did both - independently brainstormed our preferences and then followed-up with similar questionnaire list to refine our thoughts. Some of our preferences are listed below

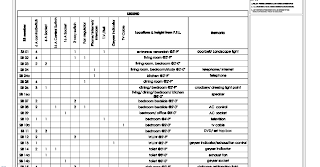

End result was when we met architect he got pretty clear picture of our likes and dislikes, our personality and that helped him build the design. As you can see from image, initial concept plan very much was in line with our requirements. We certainly were very excited seeing such a concept plan. The courtyard feature for example has been both unique as well as one that meets our expectations.

Once you have concept plan, you want to internalize it for few days. Observe how you and others who would live in the house live daily and how your house would fit-in with those habits. Note down refinements. This is also great time to re-look at those magazines, newspapers, web, for design ideas. Don't be influenced by the fancy materials and color combinations - those will come for later. Right now, you want to think about spaces and ensure your current and future needs are incorporated within them. Also, pay attention to how spaces transition from one to other to make sure it is natural. You also want to ensure that space is oriented and sized appropriately. This is the phase where structure of your house is defined and more you can glean from your research to validate or refine ideas, less you will be surprised later. This phase can take anywhere from 2-6 months depending on how many iterations it takes to finalize.

Submit plan for approvals - Once your design is finalized, architect creates plans that have to be approved by your city municipality. Depending on your state and country, requirements, process and schedule for city approval would vary. Suffice it is to say this process takes times and is easy to be overlooked. For us, it took nearly 9 months and unfortunately there is not a whole lot that one can do to make it faster.

You may want to check with your municipality, architect, contractor or any 3rd party if there are avenues to start the approval process in parallel with previous stage of house design. For example, out of 9 months, we could easily have overlapped 2-3 months had we paid some of the fees up front. Any way, in the whole end-to-end process of house building, I found this stage to be most idle and frustrating, both because it causes break in momentum and because you have no direct control. Like they say, best to not fret over things for which you can't do anything!

Meet various contractors - Depending on architect you pick, this step may or may not be necessary. When you do have the pleasure of picking a contractor, you do want to start about 3 months prior to anticipated start data of construction. That will give sufficient time to assess various contractors and also not delay construction start. Like architects, there are a number of parameters to consider

Like with picking an architect, it is difficult to find contractor that excels in all of the areas. What you want to do is identify the ones that you are willing to make compromise on and ones that you want contractor to be really strong in. Following things help you in revealing contractor's strengths and weaknesses.

Finalize a contractor - Most of the criteria to pick a contractor are also described above. The main point I want to stress here is the dynamics between contractor and architect. Again, look at house building as an exercise where you, architect, and contractor have to have the right dynamics. Architect and contractor have to communicate and trust each other as much as their equations with you.

The most important aspect is for contractor to realize that his role is that of implementer and architect has to realize his role is that of designer and inspector. Contractor therefore focuses on building good quality house within time and estimates of cost provided. Contractor can make suggestions to you and the architect but ultimately has to execute on decisions given to him.

Thankfully, we have had that equations set from day 1 and therefore it has not been as stressful experience as it could otherwise have been. I urge you to set that equation as early in the process as possible.

Start construction - Aha, finally, the day arrives when you can see some real action. It takes good 24 months from building first vision till you start construction. By now, you have accomplished huge part of house-building - assembling your team and establishing plans! You have already come half-way, believe it or not. You will soon be able to see your abstract dreams taking shape. It is start of an exciting phase in house-building. Celebrate accomplishment of this milestone !

Some best-practices to keep in mind going forward

Some of the things that we learnt about our architect and why we feel very excited about him even today -

- Coincidentally, our tastes matched much more than we originally thought. Our choices matched in picking materials, traditional design of the house, attention to detail, and standards of quality.

- Accessibility - We never had to struggle to get his time. He has been intimately involved in design. He is our direct contact and has always been very responsive.

- Flexibility - Whatever requirement we have had he has designed creative ways to incorporate them. In rare instances where we were not excited about design, he has shown flexibility to incorporate our input and revise design.

House building is a long and intimate process where architect and contractors are your trusted partners. As the owner, you should take initiative to build such a relationship as that will result in final product that everyone will feel proud to attach themselves to.

Iterate over design - You would typically meet architect to provide your requirements. Depending on architect, this meeting is either free-form or more structured. There are quite a few questionnaires available on web for design of spaces. Here is an example of questionnaire for House overall or for specific room such as Kitchen. Find one that you are most comfortable with and fill that out. This will help clarify your thoughts even if you didn't share with your architect. We did both - independently brainstormed our preferences and then followed-up with similar questionnaire list to refine our thoughts. Some of our preferences are listed below

- Open floor plan – No kitchen door, Large windows

- Vastu compliant

- Sunny in living areas

- Good air circulation

- Porous boundary between outdoor and indoor living spaces

- Environment friendly – rainwater harvesting, solar energy, composting pit, recycle water for gardening, toilets, etc.

- ...

End result was when we met architect he got pretty clear picture of our likes and dislikes, our personality and that helped him build the design. As you can see from image, initial concept plan very much was in line with our requirements. We certainly were very excited seeing such a concept plan. The courtyard feature for example has been both unique as well as one that meets our expectations.

Once you have concept plan, you want to internalize it for few days. Observe how you and others who would live in the house live daily and how your house would fit-in with those habits. Note down refinements. This is also great time to re-look at those magazines, newspapers, web, for design ideas. Don't be influenced by the fancy materials and color combinations - those will come for later. Right now, you want to think about spaces and ensure your current and future needs are incorporated within them. Also, pay attention to how spaces transition from one to other to make sure it is natural. You also want to ensure that space is oriented and sized appropriately. This is the phase where structure of your house is defined and more you can glean from your research to validate or refine ideas, less you will be surprised later. This phase can take anywhere from 2-6 months depending on how many iterations it takes to finalize.

Submit plan for approvals - Once your design is finalized, architect creates plans that have to be approved by your city municipality. Depending on your state and country, requirements, process and schedule for city approval would vary. Suffice it is to say this process takes times and is easy to be overlooked. For us, it took nearly 9 months and unfortunately there is not a whole lot that one can do to make it faster.

You may want to check with your municipality, architect, contractor or any 3rd party if there are avenues to start the approval process in parallel with previous stage of house design. For example, out of 9 months, we could easily have overlapped 2-3 months had we paid some of the fees up front. Any way, in the whole end-to-end process of house building, I found this stage to be most idle and frustrating, both because it causes break in momentum and because you have no direct control. Like they say, best to not fret over things for which you can't do anything!

Meet various contractors - Depending on architect you pick, this step may or may not be necessary. When you do have the pleasure of picking a contractor, you do want to start about 3 months prior to anticipated start data of construction. That will give sufficient time to assess various contractors and also not delay construction start. Like architects, there are a number of parameters to consider

- Quality - Contractor is the one who will realize paper-plan into real-structure. You don't want water leakage in the house after mere couple of monsoons, for example. It is critical to observe in detail houses that contractor would have built. Older the house give you better sense of durability. Newer house give you sense of attractiveness of construction.

- Speed - Some contractors tend to be fast while others can be real slow. Fast is generally good as long as that doesn't result in compromise. Contractors that are slow or have break in continuity of construction are best avoided.

- Communication - A critical factor is being able to communicate with contractor and his workers. Some contractors, especially fast ones, have number of houses going on in parallel and delegate day-to-day activities to their "managers" and workers. If these folks either don't understand the language or are not able to relate to incorporate guidance it often results in frustration and stress. It is also of great benefit if contractor is e-mail savvy as often you may just suggest your requirement through web link or pictures and it is much easier to send link rather than bring him a print-out.

- Experience - Thumb rule here is of course more the better. That would have exposed them to variety of styles, materials, architects, and owners. Each of those will help them mature and therefore be a lot more effective partner to work with.

- Resourcefulness - There are a number of functions that your contractor manages - civil, electrical, painting, carpenter, and several more. Given that these folks tend to be laborer-type, there would be an ongoing churn that contractor deals with. On top of that, depending on specific requirements of the house, contractor will need to procure specialized workers and materials. You want contractor who has alternative plans for every situation without compromising architect's vision.

- Accessibility - Contractors that delegate their job are always going to be hands-off. They also would have number of parallel construction going on and would always be time constrained. Depending on their attitude, some times we have seen they interpret architect's drawings themselves not bothering to check-in with the owner and architect. There are others who do only few houses but are thoroughly engaged in day-to-day activities.

- Estimation and planning - Contractors have to upfront estimate the cost and timeline of the project. Then, on an ongoing basis, they have to schedule mobilize material, mobilize resources, and sequence day-to-day activities, all within that high-level schedule. This skill doesn't come easily to most folks and I have yet to meet a house-owner whose house was delivered without his "micro-management". Obviously, a contractor who is able to do as much independently will offload you.

Like with picking an architect, it is difficult to find contractor that excels in all of the areas. What you want to do is identify the ones that you are willing to make compromise on and ones that you want contractor to be really strong in. Following things help you in revealing contractor's strengths and weaknesses.

- Visit as many houses that contractor built - Add combination of houses that were constructed a few years ago, to the ones that recently completed, to the ones that are under construction. Visit the house under construction few times in a week will provide snapshot their workers' day-to-day behavior.

- Talk to the house-owners whose house were recently completed or better yet are under construction. They are likely to share "horror" stories if there were any.

- Engage with contractor on detailed design and construction planning - Ask him about where he would procure material, workers, what are the specific milestones he'd shoot for, how you and him would track progress and so on.

Finalize a contractor - Most of the criteria to pick a contractor are also described above. The main point I want to stress here is the dynamics between contractor and architect. Again, look at house building as an exercise where you, architect, and contractor have to have the right dynamics. Architect and contractor have to communicate and trust each other as much as their equations with you.

The most important aspect is for contractor to realize that his role is that of implementer and architect has to realize his role is that of designer and inspector. Contractor therefore focuses on building good quality house within time and estimates of cost provided. Contractor can make suggestions to you and the architect but ultimately has to execute on decisions given to him.

Thankfully, we have had that equations set from day 1 and therefore it has not been as stressful experience as it could otherwise have been. I urge you to set that equation as early in the process as possible.

Start construction - Aha, finally, the day arrives when you can see some real action. It takes good 24 months from building first vision till you start construction. By now, you have accomplished huge part of house-building - assembling your team and establishing plans! You have already come half-way, believe it or not. You will soon be able to see your abstract dreams taking shape. It is start of an exciting phase in house-building. Celebrate accomplishment of this milestone !

Some best-practices to keep in mind going forward

- Visit your site every other day if not every day to track progress and compliance to plan

- Keep a payment chart that tracks when you made the payment, to whom, and what it was for.

- Track schedule very closely. Like any project, devil is in the details. More questions you ask architect and contractor of immediate milestones, dependency, inspection schedule, decisions that you have to make, more informed you would be.

- Ensure that you, architect and contractors meet at least once a month. Quite a few finer details get ironed out through these conversations. Preferably, these meetings should occur at the site itself.